Is it more essential to be accurate or timely?

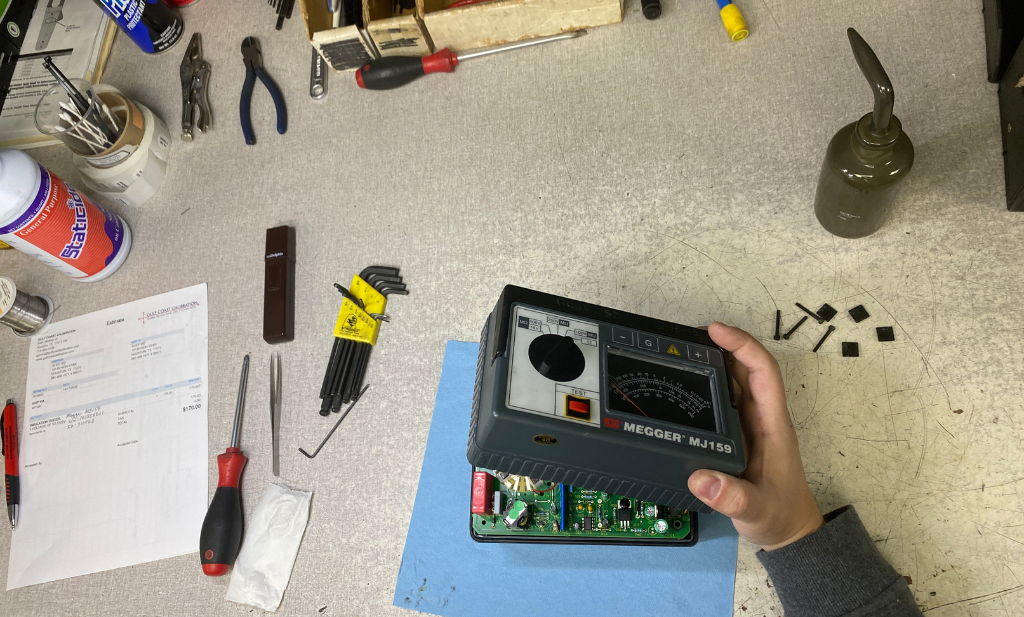

You get both when you work with Gulf Coast Calibration, A2LA-accredited calibrations lab.

Gulf Coast Calibration has been committed to producing the finest, high-precision pressure measurement and calibration systems available since 1981 – it is this international reputation for quality and service that meets your requirements for both timeliness AND accuracy.

We understand your industry and business. We support a wide range of systems in addition to our own. We understand the distinction between process time and lead time, and we guarantee 5-day or less in lead time.

Why Should You Calibrate?

The reasons for calibrating are simple. Component, equipment, and product calibration can:

- Spend less money:

Profits will rise if costs and waste are reduced through standardization. - Ensure Your Safety:

Products and components that have been calibrated work as expected and are safe to use. - Ensure High Quality:

Calibrated components and equipment will consistently create standardized products. - Reduce Production Time:

When high-quality components are available, there is no need to waste time changing out-of-spec components. - Ensure Certification Compliance:

It is guaranteed that industry rules and corporate certifications are followed. - Ascertain Accuracy:

Calibration will enable consistent reporting of product correctness. - Allows for traceability:

If necessary, calibrations can be undertaken with traceability to national standards. - Improve consistency and dependability:

Products that are manufactured to specifications perform better and endure longer. - Make up for Drift:

Regular calibration eliminates drift error. - Process Failures Can Be Prevented and Predicted:

Sensors that are reliable and precise can identify a gradual shift toward out of tolerance process conditions.

How Often Should You Calibrate?

Calibration, at its heart, is a method for determining the best approximation of the real value of a quantity being measured. There is no way to determine the exact value of a measurement, but it is feasible to come close. This proximity to the truth is what we call accuracy. Calibration is a method of ensuring that measurements collected from a device are accurate. This is accomplished by comparing the device output to a more accurate reference device. Best practices necessitate that this reference device be traceable to a national or international standard in SI units.

Some sensors wander more than others. Manufacturers typically have a reasonable notion of how long a sensor will take to drift out of tolerance. A “calibration interval” will be recommended by a manufacturer based on their expertise and the inherent calibration stability of a sensor. The calibration interval is often specified in the sensor’s specifications. The term “recommendation” indicates some freedom in extending or shortening the period based on an individual sensor’s continuing history. Some sensors may remain in tolerance for a longer period of time than others. In practice, the user must decide whether to re-calibrate depending on their experience with each sensor.

Call us to discuss your calibration, test or repair needs at:

713.944.3139.

Request for Calibration Quote

Request for PPE/Glove Testing Quote