PPE Rotation Management Program

Ensuring Safety and Compliance

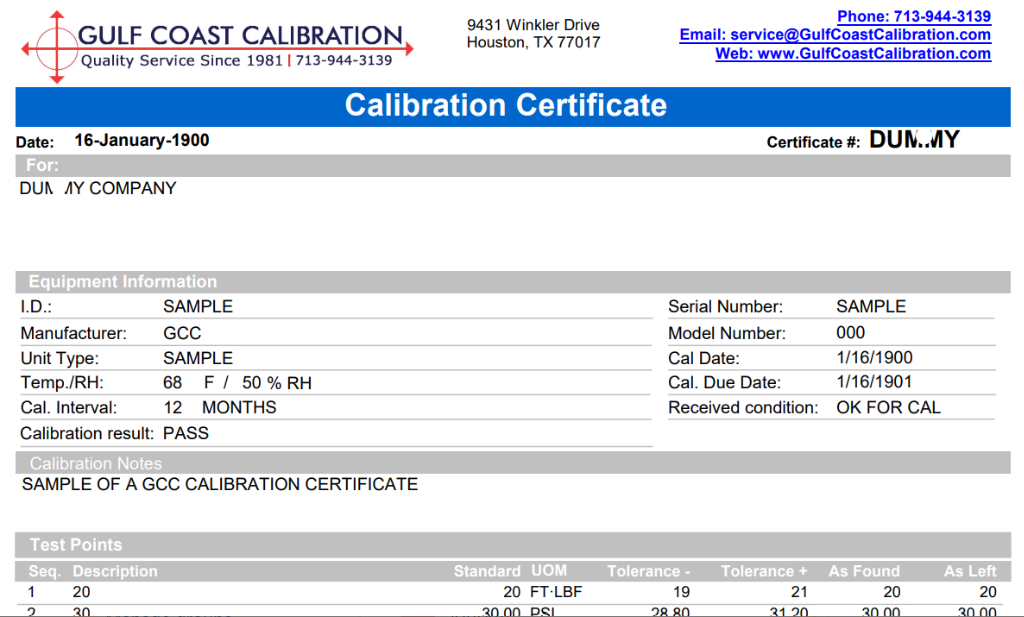

As an industry leader in calibration and safety services, Gulf Coast Calibration (GCC) is committed to safeguarding your workforce. Our PPE Rotation Management Program ensures that your employees have access to clean, reliable personal protective equipment (PPE) while adhering to all OSHA safety standards.

Why PPE Rotation Matters

Effective PPE rotation is crucial for maintaining safety and compliance in hazardous work environments. Here’s why it matters:

-

Safety: Regularly rotating PPE minimizes wear and tear, ensuring that equipment remains effective. Clean, well-maintained gear reduces the risk of accidents and injuries.

-

Compliance: OSHA mandates proper PPE usage and maintenance. Our program helps you stay compliant by managing rotations efficiently.

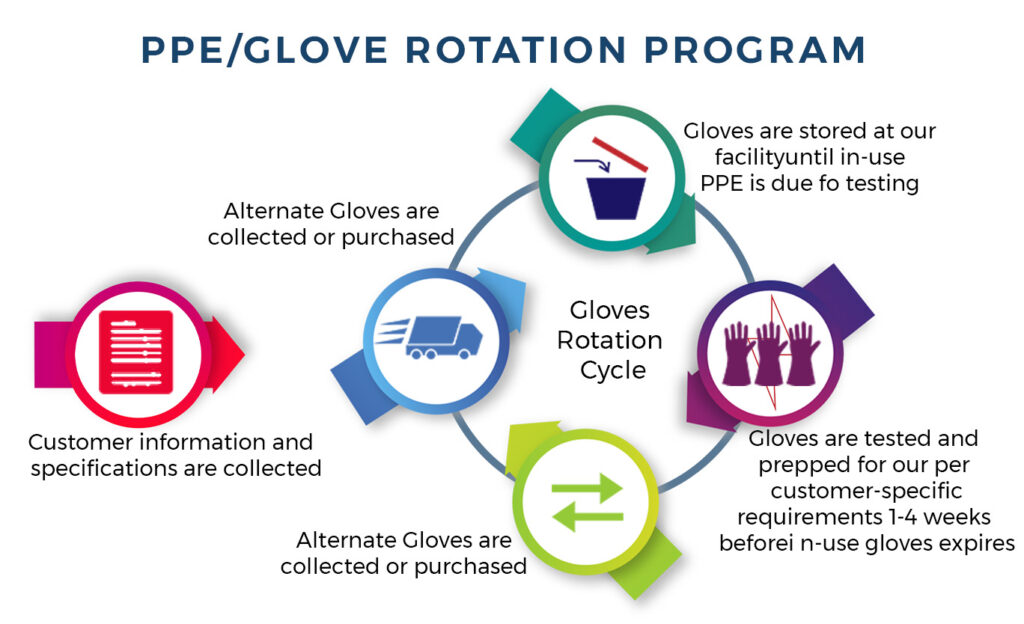

How Our Program Works

-

Enrollment: Sign up for our PPE Rotation Management Program. We offer free pickup and delivery, making the process hassle-free for your team.

-

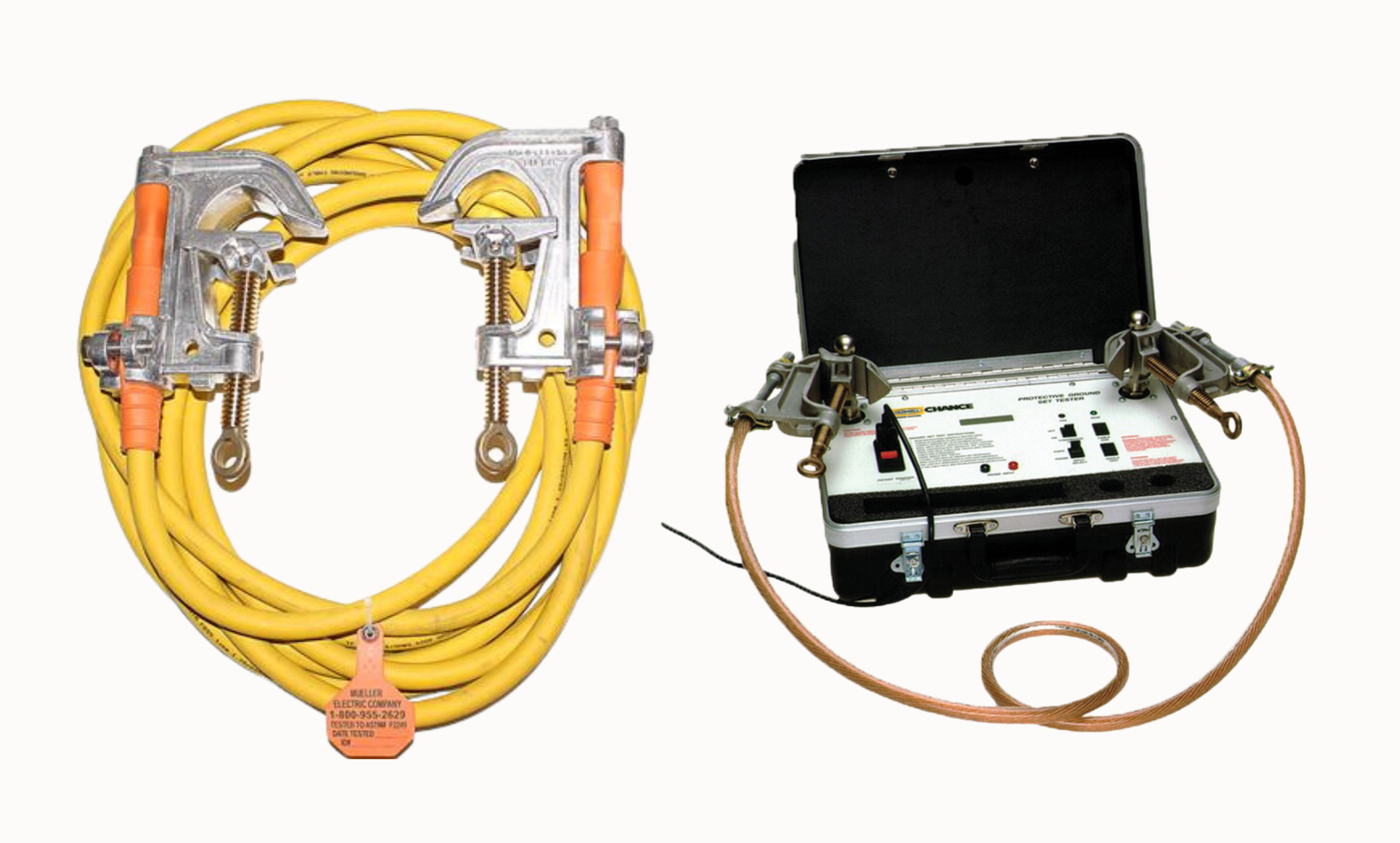

Seamless Process: Our experts handle the entire rotation process. From collecting used gear to delivering freshly calibrated replacements, we ensure a seamless experience.

-

Arc Flash Suits: We specialize in arc flash suit inspection, cleaning, and repair. Our program keeps your team protected with reliable suits.

Benefits of Choosing GCC

-

Expertise: With decades of experience, GCC understands the unique requirements of various industries.

-

Efficiency: Our streamlined process saves you time and effort, allowing your team to focus on core tasks.

-

Compliance Assurance: We keep you compliant with OSHA regulations, reducing the risk of penalties.

-

Peace of Mind: Knowing that your team has access to well-maintained PPE provides peace of mind.

Conclusion

Investing in a robust PPE Rotation Management Program is an investment in safety, compliance, and peace of mind. Trust GCC to keep your workforce protected and your operations running smoothly. Enroll today and experience the difference!

Request for Calibration Quote

Request for PPE/Glove Testing Quote