Weighing and measuring equipment is used in industries ranging from pharmaceutical manufacturing to military contracts to ensure compliance, precision, and safety. Unfortunately, due to normal wear and tear, every measuring instrument loses its effectiveness over time. Calibrating your measuring equipment has various advantages, including increased instrument life, more precise results, simpler certification, and lower expenses.

When it comes to calibrating your equipment, you need a calibration laboratory you can rely on for efficiency and peace of mind. Here are some things to think about when selecting calibration services for your equipment.

Accreditation

One of the characteristics to look for in a calibration lab is if it is third-party accredited. It is critical to work with a calibration service provider who has been accredited by third-party standardization bodies. This is because certification verifies the accuracy of a lab’s calibrations. When you work with an approved calibration laboratory, you can be confident that they satisfy quality assurance standards.

Look for a calibration service provider who has been accredited by numerous standardizing agencies. Some of the most valuable calibration lab accreditations are:

- ISO/IEC 17025:2005

This certification is provided by the International Organization for Standardization (ISO) and specifies the competence, consistency, and impartiality of a laboratory. ISO/IEC 17025 certification is commonly seen as a fundamental indicator of a laboratory’s competency. The standard is divided into five sections: general, management system, structure, resources, and process.This standard is critical for any calibration laboratory to meet since it improves a lab’s industry reputation and promotes efficiency, performance, and compliance.

-

ISO 9001

ISO 9001 is another important standard. Although ISO 9001 is not as specifically aimed at calibration laboratories as ISO/IEC 17025, it is an essential part of implementing a quality management system (QMS). A quality management system (QMS) is a set of practices meant to help a company improve continuously.ISO 9001 certification may help any company that wants to provide high-quality products. The standard requires companies to document their operations in order to generate a QMS handbook. The accreditation procedure also includes regular audits by a certifying agency.

Capabilities

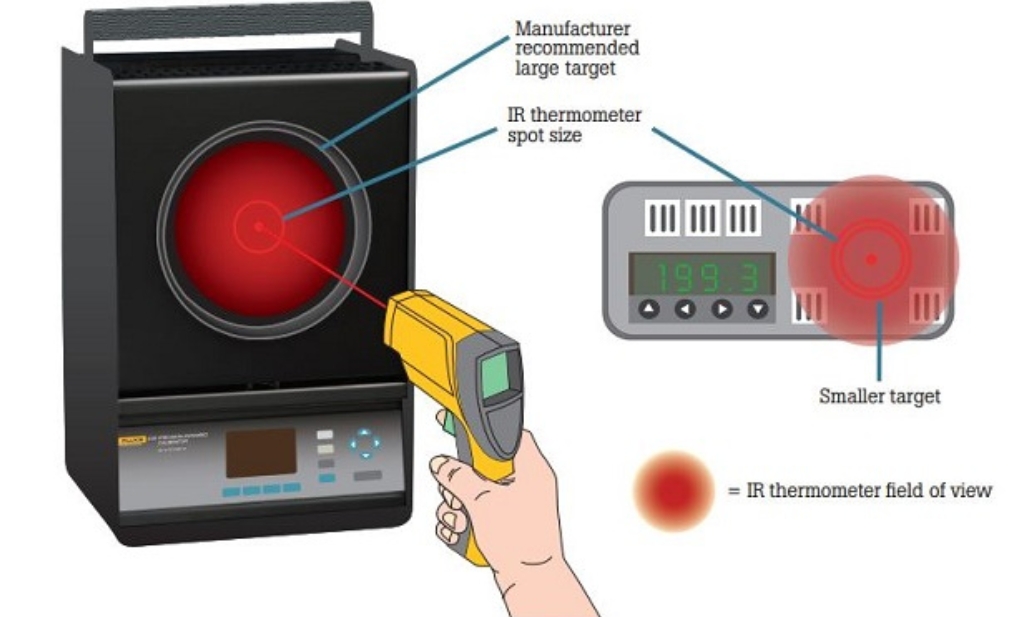

Precision calibration is critical for assessing the accuracy and effectiveness of your equipment. With so many sectors relying on metrology equipment, calibration laboratories must have the skills and capabilities to operate with a wide range of equipment. Calibration of a thermometer, for example, differs from calibration of a sensor.

A reputable calibration service provider can fulfill all of your calibration requirements, including:

- Calibration of Pressure and Vacuum

Pressure gages are widely used in food and beverage processing plants, labs, oil refineries, and other scientific settings. Pressure and vacuum calibration employ computerized pressure modules to determine if pressure gages produce reliable data, assisting organizations in meeting customer expectations and adhering to industry standards. - Mass and torque calibration

Torque devices are used during production when the automotive and machine manufacturing sectors need to measure torque. Manufacturers can guarantee their devices transmit the proper tension to the fastener by performing frequent torque and mass calibration. - Calibration of Electronics

Electrical characteristics such as current, voltage, resistance, time, and frequency must be measured in a variety of businesses. Electrical calibration is performed in calibration labs using calibration equipment that has been certified against standards from independent regulatory authorities. - Surface Plate Calibration and Resurfacing

For accurate measurements, surface plates must fulfill flatness standards. These plates may have peaks or depressions from wear, indicating that they should be resurfaced on a regular basis. Surface Plate Calibration and Refinishing are critical for ensuring that goods satisfy industry requirements.

Accuracy

You want your company’s measurement equipment to be as precise as possible. Accurate calibration equipment can provide more precise findings, boosting the usefulness of your equipment.

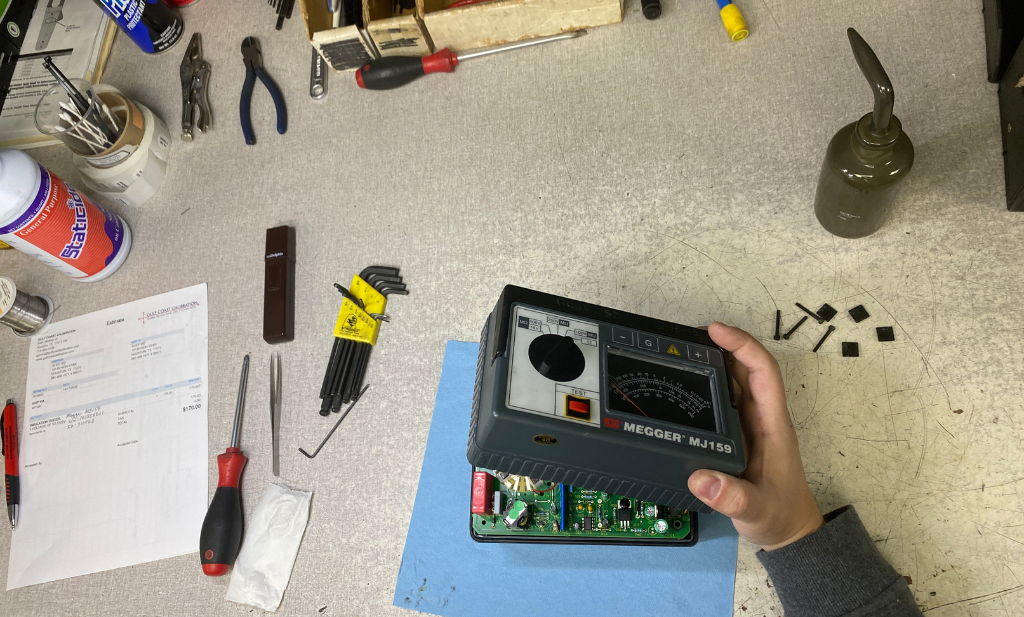

A reliable calibration facility will either send a qualified technician to your location or calibrate your equipment in a laboratory. During the calibration procedure, the technician will compare your instrument’s measurements to a standard to check if they match.

If your equipment produces a reading that differs from the norm and falls outside of the standard accuracy ratio, the technician will discover the problem. They will then tweak your instrument till the reading is accurate.

Service To Customers

One of the finest traits of a calibration lab is a commitment to client service. Calibration must be done on a regular basis, perhaps as frequently as every few months, depending on how frequently the device is used. Developing a professional partnership with a full-service calibration service provider guarantees that the calibration process runs smoothly and that your equipment satisfies expert requirements.

Here are some of the customer service advantages to look for in a calibration lab:

- Knowledgeable technicians: When acquiring on-site calibration services, you want professionals that understand the processes required to calibrate your unique equipment. Look for a trustworthy calibration business that has properly trained specialists that can do on-site calibration.

- Fast turnaround: When you need equipment calibration services but want to avoid costly downtime, look for a calibration company with fast turnaround times. You should be able to ask a calibration laboratory about how long it takes them to service equipment. Few manufacturers can afford to be without an essential piece of equipment for months as they wait for calibration. Look for a calibration laboratory that can complete the calibration in a few days.

- Multiple ways to calibrate: Many calibration labs will perform field calibration, where they send a technician to your company’s location to perform the calibration on-site. While this method saves time on shipping, calibration may not work if temperature and humidity interfere with sensitive devices. Look for a calibration service provider that offers multiple calibration methods, including on-site and laboratory calibration. If the lab provides regional pickup and delivery, that’s another bonus.

Experience

When it comes to measuring precision, you need experienced calibration services to assure the functioning of your equipment. Consider hiring a calibrating business with years of expertise. Working with an expert calibration service provider has the following advantages:

- Precision calibration services on a full-service basis.

- Professional, experienced specialists that can solve equipment difficulties.

- Services for equipment repair.

Let Gulf Coast Manage Your Calibration Schedule.

Are you looking for calibration services, or is your equipment producing out-of-the-ordinary results? If so, you’ve come to the right place. Gulf Coast Calibration has over 40 years of expertise and has developed to become one of the Gulf Coast region finest weighing equipment and calibration firms. Our calibration services, which encompass equipment in a variety of sectors, are provided through our in-house laboratory or on-site at our clients’ facilities.

Call us to discuss your calibration, test or repair needs at:

713.944.3139.

Request for Calibration Quote

Request for PPE/Glove Testing Quote