Electrical Calibration: A Vital Safeguard Against Electrocution

Introduction

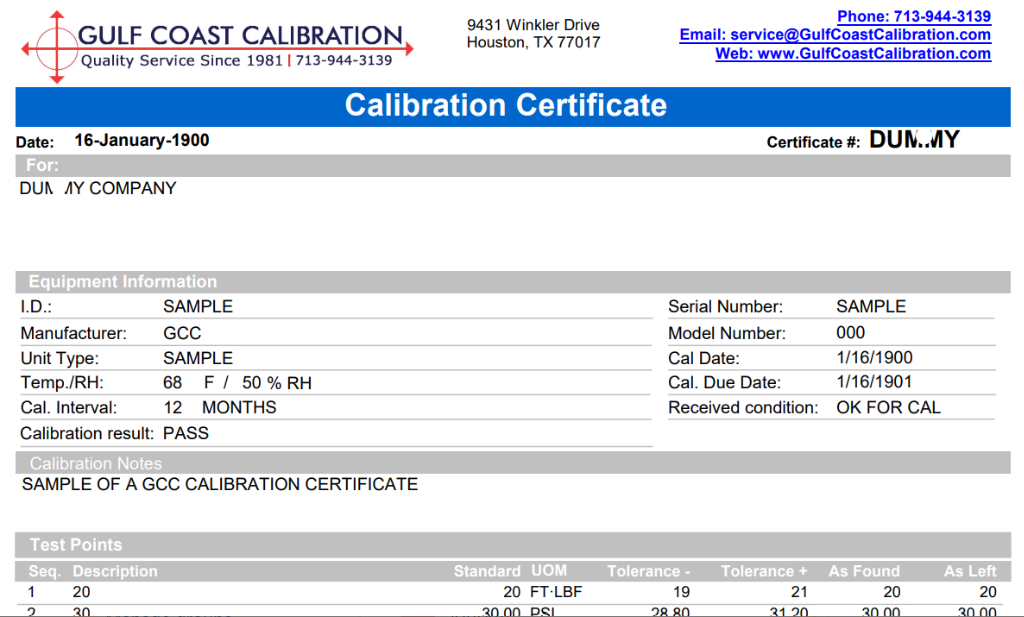

Electrocution is a grave hazard that lurks in workplaces, threatening the safety of workers across various industries. At Gulf Coast Calibration, we recognize the critical importance of preventing electrical accidents. Our specialized electrical calibration and repair services play a pivotal role in safeguarding lives and ensuring a secure work environment.

Understanding Electrocution in the Workplace

Electrocution occurs when a worker is accidentally shocked by electricity, leading to injury or even death. It’s one of OSHA’s “fatal four,” emphasizing its severity. Whether on construction sites, in factories, or office spaces, exposure to electricity poses risks. Faulty equipment, inadequate training, and non-compliance with safety protocols contribute to this peril.

The Role of Electrical Calibration

1. Ensuring Accurate Measurements

Electrical instruments must provide precise measurements to prevent mishaps. Our calibration services meticulously verify the accuracy of voltmeters, ammeters, and other devices. By calibrating regularly, we minimize measurement errors, reducing the chances of faulty readings that could lead to dangerous situations.

2. Detecting Faults Early

Faulty equipment is a breeding ground for electrocution risks. Our calibration process includes thorough inspections, identifying any deviations from expected performance. Early detection of faults allows timely repairs, preventing potential hazards.

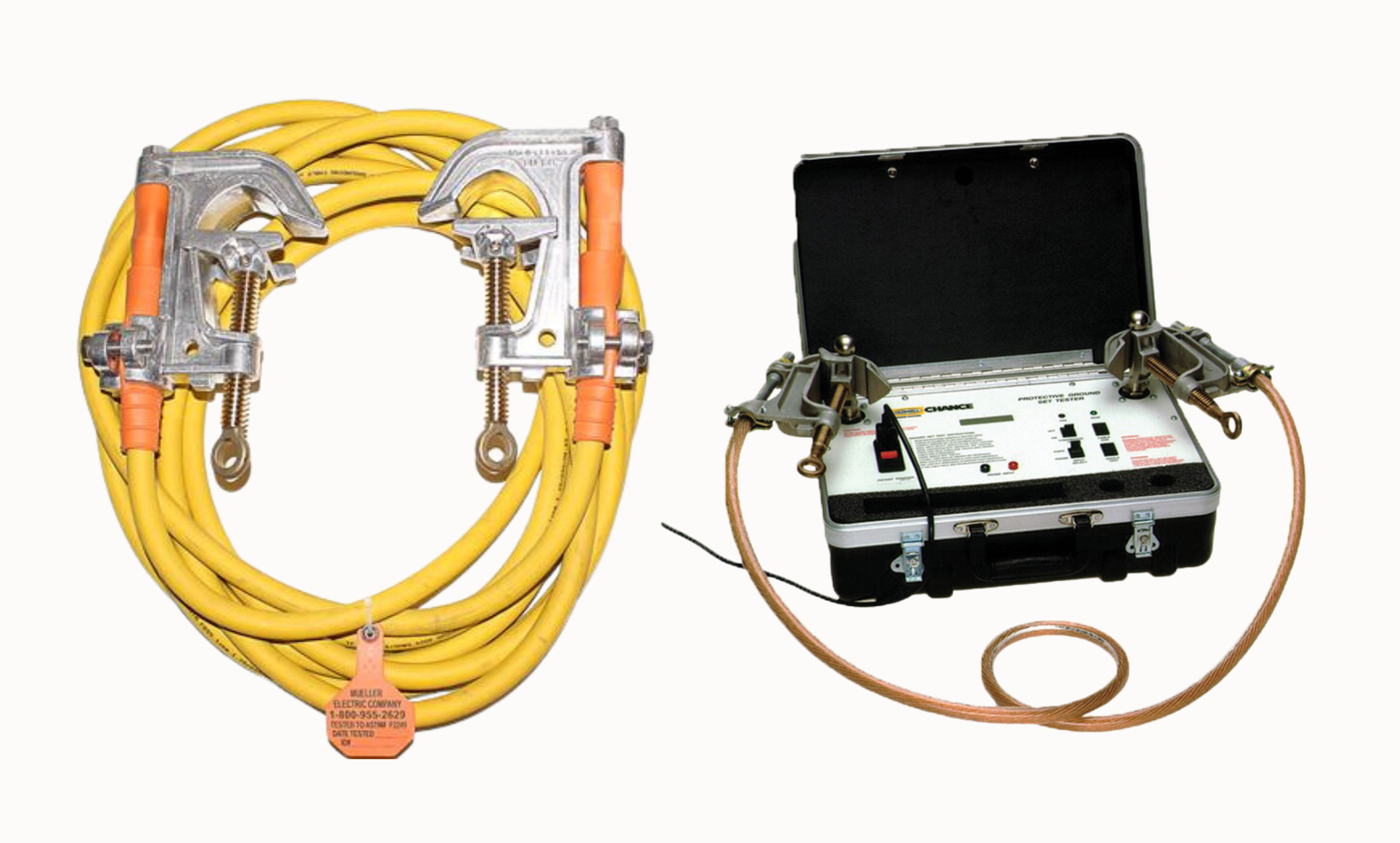

3. Proper Grounding

Grounding is crucial for electrical safety. Our calibration experts ensure that all equipment is properly grounded. A low-resistance path connecting to the earth prevents voltage buildup, minimizing the risk of electric shock incidents.

4. Compliance with Safety Standards

Calibration ensures adherence to safety standards. We follow industry guidelines and OSHA regulations, ensuring that equipment operates within safe limits. Compliance reduces the likelihood of electrical accidents.

Repair Services: Addressing Vulnerabilities

1. Timely Repairs

When faults are detected during calibration, our repair services kick into action. Whether it’s faulty wiring, damaged insulation, or malfunctioning components, we address issues promptly. Timely repairs prevent potential electrocution scenarios.

2. Equipment Upgrades

Outdated or worn-out equipment poses risks. Our repair services include upgrades, replacing obsolete components with modern, safer alternatives. Upgraded equipment enhances workplace safety.

3. Expert Technicians

Our skilled technicians handle repairs with precision. From fixing frayed cables to replacing faulty circuitry, their expertise ensures that equipment operates optimally, minimizing electrocution risks.

Conclusion

At Gulf Coast Calibration, we take pride in our role as electrical safety guardians. Through meticulous calibration and timely repairs, we contribute to preventing electrocution in workplaces. Remember, safety isn’t an option—it’s a necessity. Let’s work together to keep our workforce safe and secure.

Request for Calibration Quote

Request for PPE/Glove Testing Quote